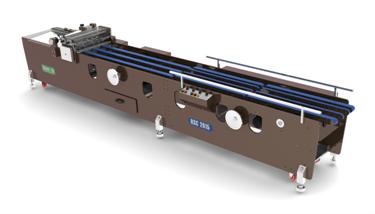

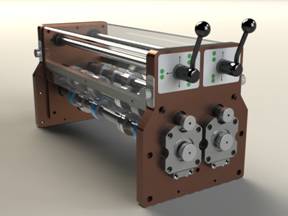

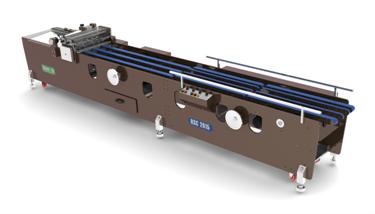

RSC 2010 Transport

Product Capacity: Width: 2-20.5” / Length: 4-24” (DOT)

Max speed: 450’/minute

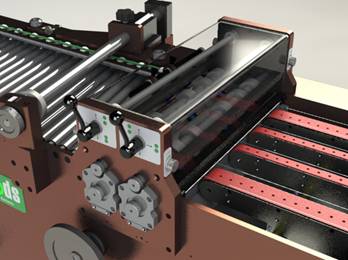

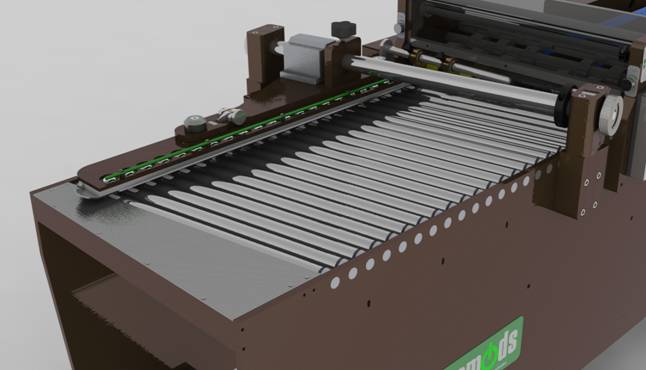

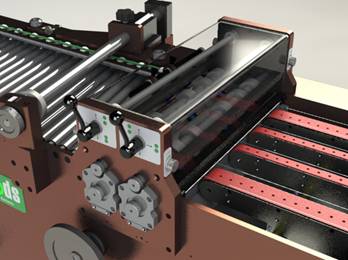

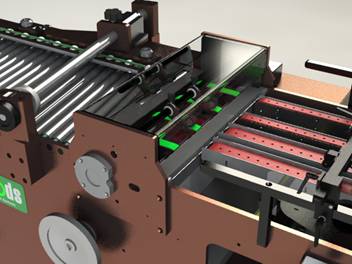

RSC 2010 (Right) Register/Scoring/Perforating/Slitting/Tipping/Folding Conveyor – Provides means for precision registration and scoring - whether in-line or at a 90 – Quality without compromise – Dual scoring module provides absolute precision and control of scores, perfs and slitting (sold separate) – Diverter feature removes doubles/failed QC inspected products. – VMC section(s) perform plow folding, product tipping, flipper plate and other processes with quiet and effortless set-up. – Our conveyors use the latest technology in vacuum – the most effective systems available today.

We effectively score and plow 20# bond in “C” and “Z” fold.

Features/Attributes:

- Virtually all tool-less adjustments

- ½” Anodized aluminum frames

- Automatic vacuum modulation

- Micro-adjust side & skew edge-guide

- Parallel exit roller

- Urethane nip wheels w/ball bearings

- Ultra precise scoring/slitter module

- (2) 3’ VMC transport sections

- Storage drawer

- Easy to set-up/maintain

- Ultra smooth drive-train

Optional Components:

- Transfer module

- Parallel infeed rollers

- Scanners

- Doubles detection

- Plows

- Tipper plate

- QC diverters

- Speed following drive system

Units can be customized for your application - Right to left option also available

Base Features:

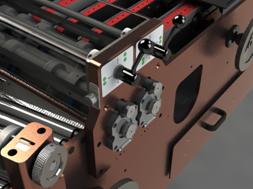

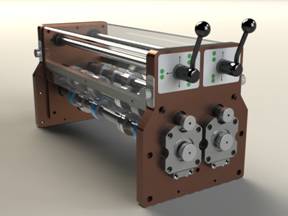

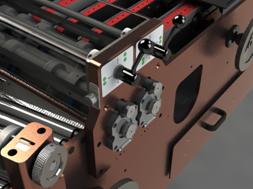

Handwheels:

Assists in fast - precision set-ups – These are clutched for safety

OP Console:

Simplistic design assures no language barrier or confusion as to function –

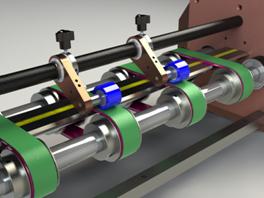

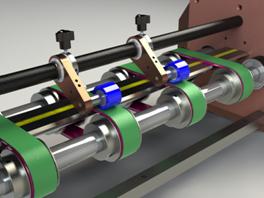

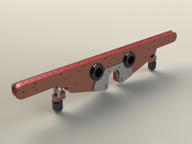

Roller Register:

Features:

- Infeed/transfer parallel rollers

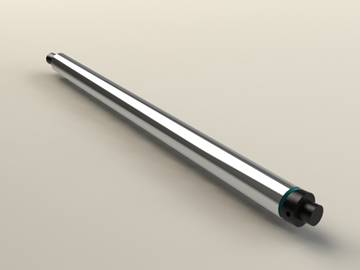

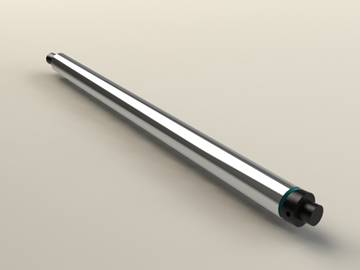

- Stainless steel rollers and shafts

- Large sealed bearings

- Vibration dampening

Register Guide

- Hardened steel shaft w/mating linear bearing

- Precision adjustments w/built in scales

- Slop-Free

- Lower Traction Roller Drive

- Urethane coated Drivebelt

- Contoured parallel roller wrap

Parallel Exit roller

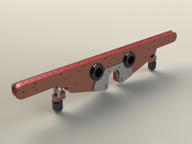

Transfer Roller:

Assists in product entering scoring module or transfer module – Bridges excess gap – Assists in registration – Engineered to prevent “buckling”

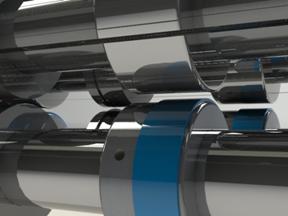

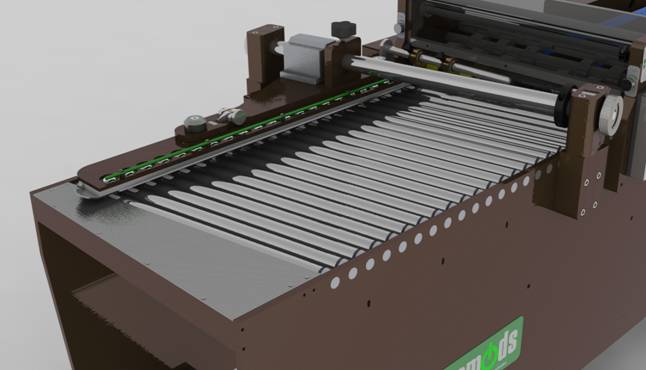

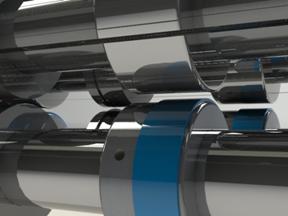

Tube Design:

Stainless steel tubes with vibration isolators and ball bearings – Each tube can be easily removed independently in the event of service or repair.

Register Guide:

Engineered for absolute precision – Utilizes a industry standard design with enhanced features

- Hardened steel linear shaft

- Precision lateral micro-adjust

- Precision skew micro-adjust

- Premium Linear Bearing

- Run-out (Slop) free design

- 1-1/4” Transfer balls

- 3/8” Product capacity

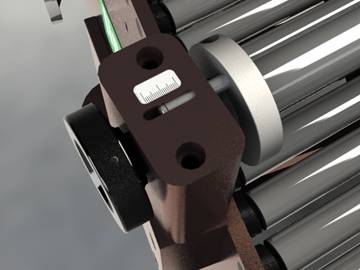

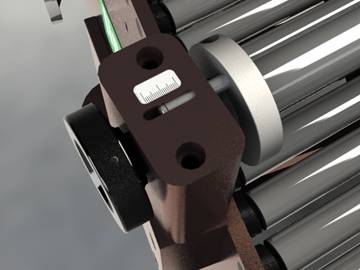

Main Side Adjustment:

Designed for quick, smooth lateral adjustment, Features a maintenance-free precision linear bearing and a non-marring, soft grip locking knob – Shaft is precision ground and hardened (C58). The combination of these items equate to a maintenance-free smooth operating adjustment.

Micro Side-Guide Adjustment:

Designed for precision adjustment, Features built-in recessed scale - 1 turn = .070” (mm or inch scales available) – Run-out free design

Micro Skew Adjustment:

Tool-less skew adjustment features a large knurled thumbscrew - 1 turn = .1 degrees

Enhanced Roller Drive:

Urethane coated belt provides extra grip - Belt partially wraps each tube providing consistent drive / response on all rollers.

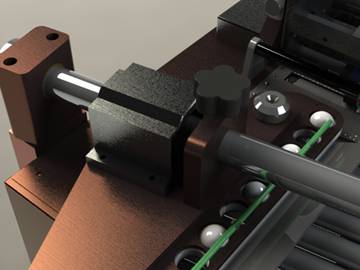

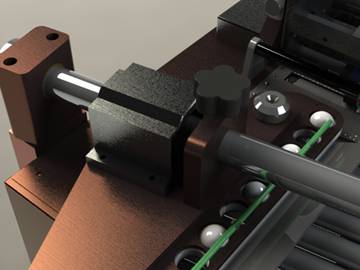

Scoring or Transfer Module

Provides the option of future expandability – Units can be interchanged in less than ½ hour

|

|

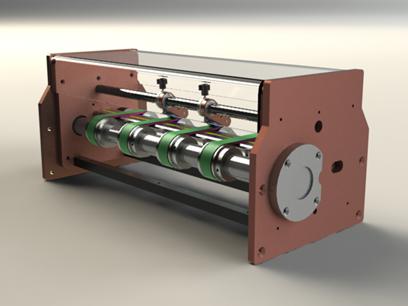

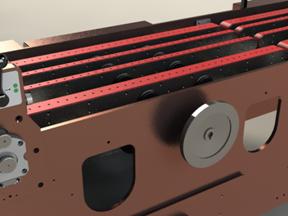

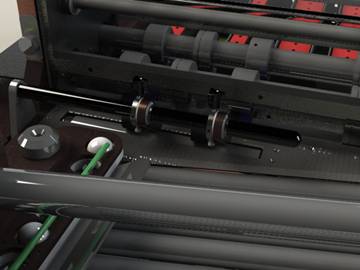

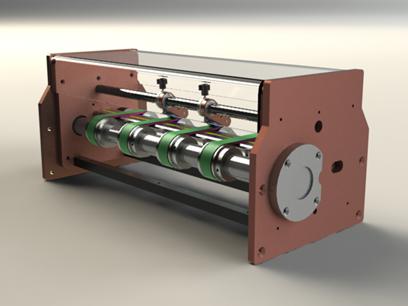

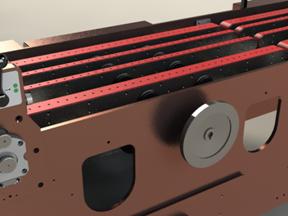

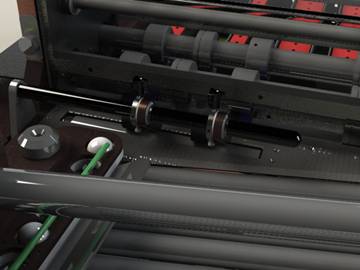

Scoring module:

Used for scoring, perforating or slitting paper

2 Minute Access |

Transport Module:

Ink jetting, scanning, QC verification, gluing and more – provides simple option when scoring unit may interfere – Books, rigid products, etc… |

Modules/machines for custom rotary options

Please inquire on your project needs!

Scoring/Perfing/Slitting Module:

Scoring/Perfing/Slitting Module:

- Super easy collar maintenance (under 5 minutes)

- Designed for use with 35mm x 58mm scoring/perf collars

- Large ball bearings (R16 &R20)

Optional:

- Parallel helical drive gears (to drive upper roller)

- Scoring collars/slitters to your preference and qty

Engagement Levers:

Accurately actuates upper shafts to apply precision scores or perfs – 3 positions: up is “off”, horizontal is “adjustment mode” and down indicates “on”. Once set, levers stay put…

Pressure Micro Adjust:

Pressure Micro Adjust:

Parallel/Micro Adjustment - Truly is a micro adjustment.

1 turn = .0005”

Urethane Drive Collars:

Provides absolute grip in product without “buckling”

Easy adjustment and maintenance

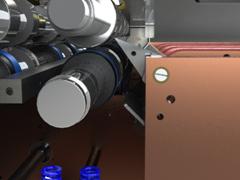

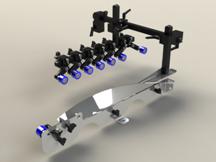

Transfer Module (optional)

- Rubber/Urethane coated drivebelts

- Urethane nip wheels

- Built-in scale

- Custom brackets to fit your needs

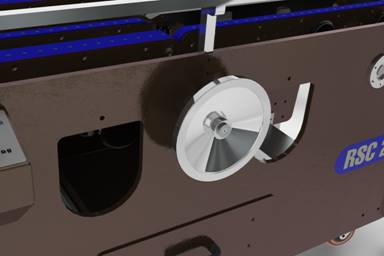

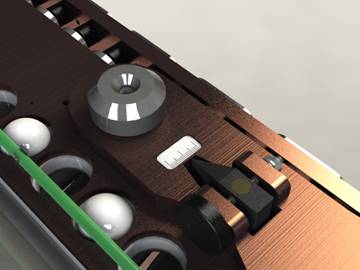

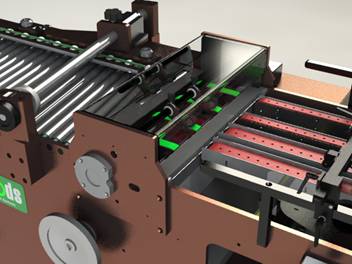

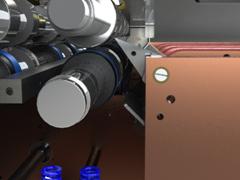

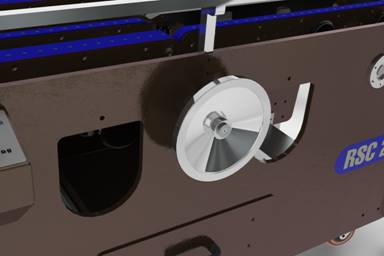

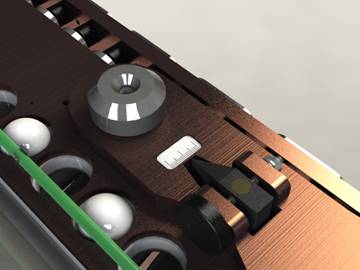

Built in Diverter System:

|

|

|

Pass-Through Mode |

Divert/Reject Mode |

Diverter Drawer |

The diverter is an optional “built in” item, uses 24VDC signal to engage/disengage

Actuator air driven @ 35PSI or less

Common Controllers Used:

Bar Code (scan for missing or incorrect bar codes)

Print scanner (scan for missing print, which can be caused from double sheets during sheet-fed printing)

Height scanner (scan for pre-tipped product thickness)

Or use drawer for parts storage.

VMC Transports

|

|

Plow, Tip, Scan, Flip, Separate, Side Register |

|

2” Width |

|

1” Width |

3’ or 5’

VMC Transport Sections

Simple operation, adjustment and maintenance

All large bearings throughout

(12 R10s per tube) –

Allows up to 2 degrees of angle for stream separation

We can build your system(s) to any preferred configuration using 3’ and 5’ VMC units.

Max sub unit length 15’ or you can order as modular.

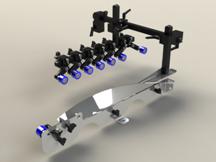

Plows:

Plows:

Ultra-fast set-ups

- 12ga stainless steel construction

- #8 mirror finished

- Premium quality in all components

Performance engineered – You asked we listened:

Rubber coated drive-belts

High quality deck components

High performance / “stall-free” vacuum system

Virtually tool-less/non marring adjustments

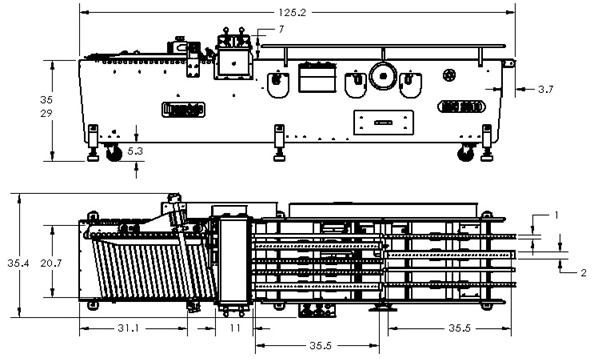

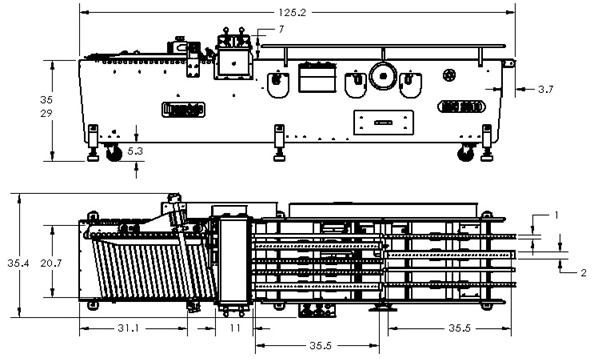

RSC 2010 Machine Footprint:

General Machine Specs:

L: 125.2”

W: 35.4”

H: 29-35”

Weight: Apprx.1250 lbs.

Power: 230VAC Single Phase/20A

Air: 5CFM @ 35PSI - Max

Scoring/Perfing/Slitting Module:

Scoring/Perfing/Slitting Module:

Pressure Micro Adjust:

Pressure Micro Adjust: